HIGH PERFORMANCE PACKING

Pioneer company of high-performance packing

as the high-performance filling for needs of the customer.

Irregular filling

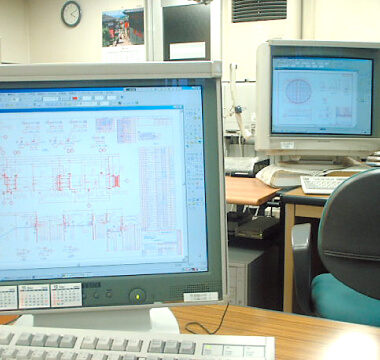

Internals design by CAD

Drafting

CADSUPER FX for Windows Ver.7.0

3D

Solid Builder Ver.2.0

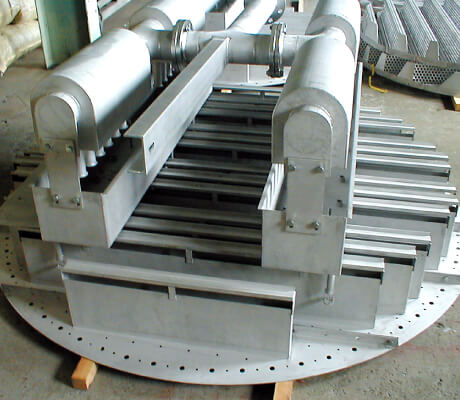

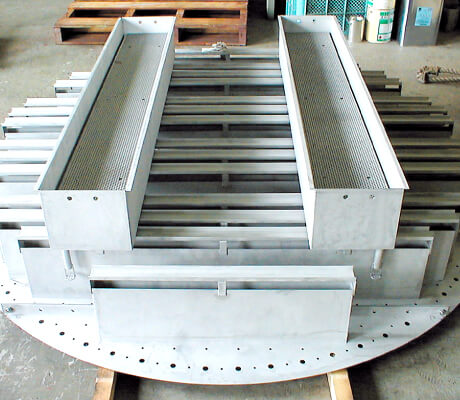

Decentralized test of distributer

Feed pipe & Tarff

Distributer

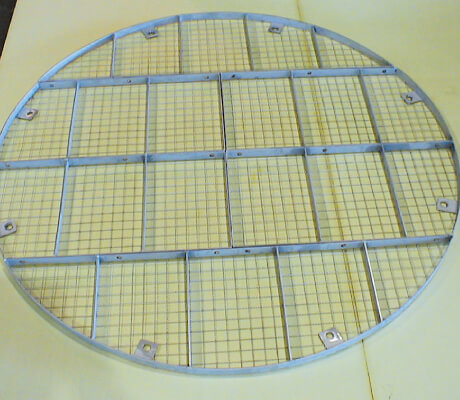

Packing support

Hold down plate

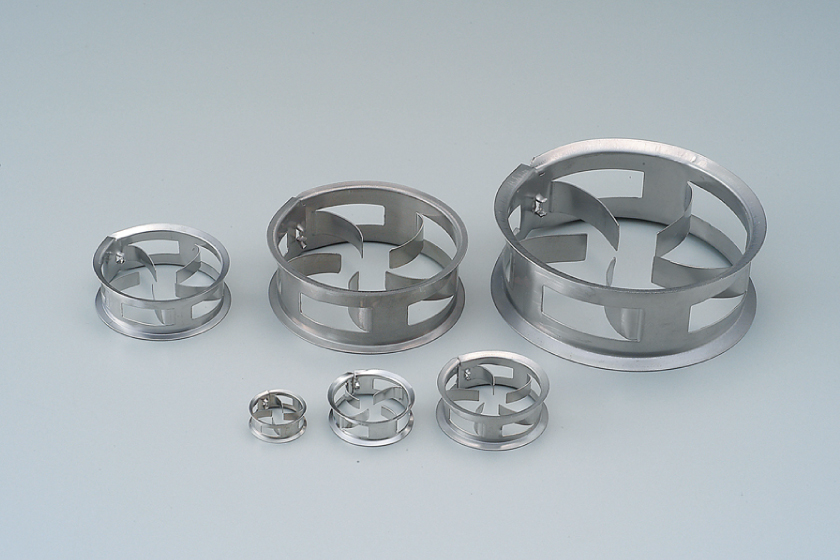

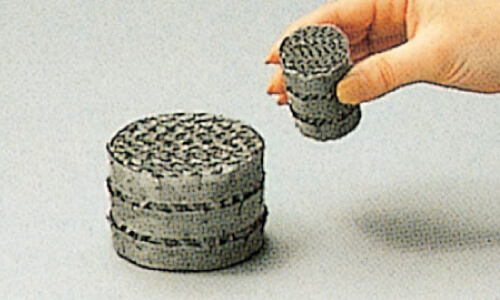

SANREI MINI RING【MR】

Metal ring

| Size | Measurement (mm) |

Gravity of fillings (kg/㎥) |

Free volume (%) |

Packing factor F(1/ft) |

|---|---|---|---|---|

| No.0 | 17φ × 6H | 320 | 96 | 55 |

| No.1 | 25φ × 8H | 290 | 96.5 | 40 |

| No.1.5 | 34φ × 11H | 230 | 97.2 | 29 |

| No.2 | 43φ × 14H | 180 | 97 | 22 |

| No.2.5 | 51φ × 17H | 158 | 97.3 | 18 |

| No.3 | 66φ × 21H | 165 | 97.6 | 14 |

| No.4 | 86φ × 28H | 120 | 98.3 | 10 |

| No.5 | 131φ × 41H | 110 | 98.6 | 8 |

Materials: SUS 304,316, titanium, Hastelloy, Aluminum etc.

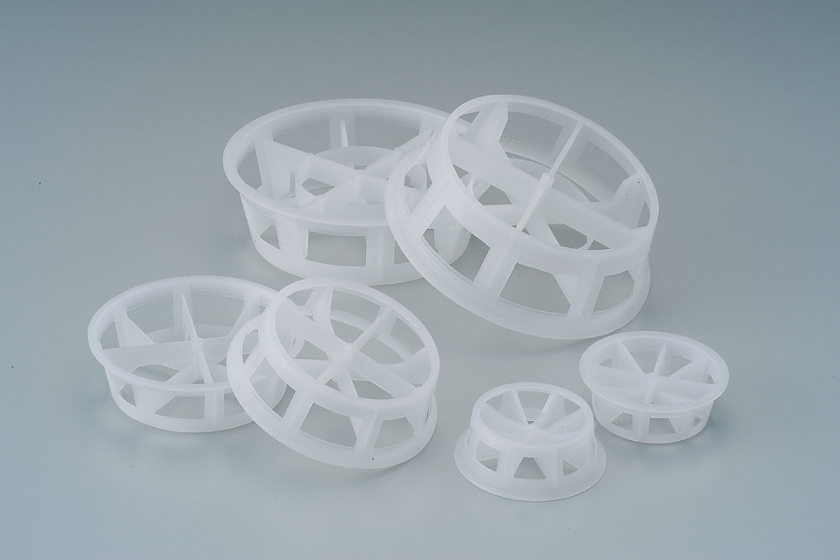

PLASTIC SANREI MINI RING【MR】

Plastic mini ring

| Size | Measurement (mm) |

Gravity of fillings (kg/㎥) |

Free volume (%) |

Packing factor F(1/ft) |

|---|---|---|---|---|

| No.1A | 50φ × 39φ × 17H | 92 | 92 | 30 |

| No.2 | 75φ × 61φ × 22H | 55 | 94 | 15 |

| No.3A | 104φ × 84φ × 32H | 41 | 95 | 12 |

Materials: PR, PVC, PE, PFA, PVDF etc.

※gravity of PP made ring

Strong point of the mini ring

- The Hight oppose the filling diameter is 1/3.

- Irregular fillings makes more close to regularly fillings (Better reproducibility).

- It is a little density against other general-fillings (Paul ring etc.).

- Gas and liquid channeling is small (Channeling is little).

- The number of fillings per unit cross-section area is large and vapor-liquid contact is not only surface area but also droplet detachment surface renewal more contact efficiency (Heat, mass transfer).

- Ration of general-ring, △P is small and difficult to foam, and the lot is little accumulated and easily.

- △P is small – the amount of steam is decreasing and able to reduce

- Blower power is lower

- Through put is increase

- Tower diameter can be small

- Mist entrainment (entrainment) is decrease

- Hard to foam

- Dirt line – acetic acid plant, ammonium plant etc.

- Polymerization line – acrylonitrile, MMA, acrylic acid etc.

- Decentralization flow down, filling is a little diffusion, so it is needed to attention to distributing sheet. Even more, filling by a layer is high against general-filling (Maximum Hight of filling is 7 times of tower diameter or absolute Hight is 10m).

- Flow rate range (max 800㎥/㎡ HR), and operation range is large.

- Scaling up is easy

- Liquid of large surface tension is operation also small efficiency of deterioration.

- Low price of filling and filling operation control is little and cost is cheap.

- Tower diameter (D) and general filling (d), D/d is over MIN.6, standard value is over 8.

- Sanrei’s mini ring’s slip part of hook is hard to snaggle between fillings, and hard to happen nesting.

- Changing tray or general fillings etc. of the already-existing tower, it is complete improving tower (separation, absorption) decreasing liquid volume (reflux, absorbing liquid etc).

- Metal minoring can make all kinds of metals. Iron (carbon steel) stainless steel (3044, 316etc.), aluminum, titan, Hastelloy etc.

- Result of using is plentiful.

METAL RASCHIG RING【MR】

Metal ring

| Size (inch) |

Thickness (mm) |

Gravity of fillings (kg/㎥) |

Free volume (%) |

|---|---|---|---|

| 0.4 | 638 | 92 | |

| 0.5 | 705 | 91 | |

| 1″ | 0.6 | 480 | 94 |

| 0.8 | 423 | 95 | |

| 2″ | 0.8 | 329 | 96 |

| 3″ | 1.0 | 286 | 96 |

Attention: Weight, for example SUS 304 (specific weight 7.93), Note. Weight. AT. S.G. 7.93. OF St. St. 304.

METAL PALL-TYPE RING

Metal ring

| Size (inch)(mm) |

Thickness (mm) |

Gravity of fillings (kg/㎥) |

Free volume (%) |

|---|---|---|---|

| 0.4 | 638 | 92 | |

| 0.5 | 705 | 91 | |

| 0.5 | 515 | 94 | |

| 1″ (25.4) | 0.6 | 480 | 94 |

| 0.8 | 423 | 95 | |

| 2″ (50.8) | 0.8 | 329 | 96 |

| 3″ (76.2) | 1.0 | 286 | 96 |

Attention: Weight, for example SUS 304 (specific weight 7.93), Note. Weight. AT. S.G. 7.93. OF St. St. 304.

CERMIC RASCHIG RING

Porcelain rushing ring

| Size (inch)(mm) |

Gravity of fillings (kg/㎥) |

Free volume (%) |

|---|---|---|

| 1,250 | 45 | |

| −− (10) | 840 | 63 |

| 860 | 64 | |

| 670 | 71 | |

| 580 | 75 | |

| 1″ (25) | 610 | 73 |

| −− (35) | 720 | 69 |

| 2″ (50) | 620 | 73 |

| 3″ (75) | 700 | 73 |

※Specific gravity : 2.29 for ceramic material(ratio 2.29)

CERAMIC SADDLE

Ceramic material ring

| Size (inch)(mm) |

Gravity of fillings (kg/㎥) |

Free volume (%) |

|---|---|---|

| 721 | 78 | |

| 1″ | 705 | 77 |

| 673 | 80 | |

| 2″ | 673 | 79 |

| 3″ | 593 | 80 |

※Specific gravity : 2.29 for ceramic material(ratio 2.29)

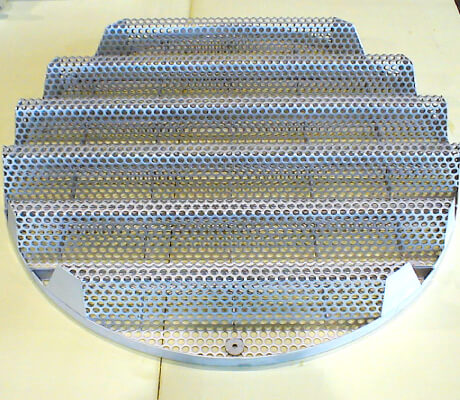

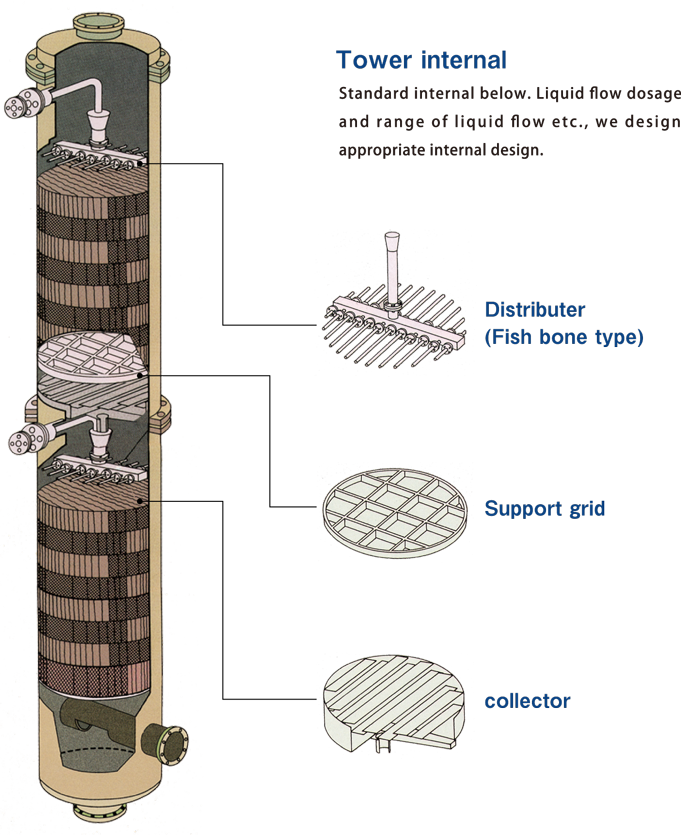

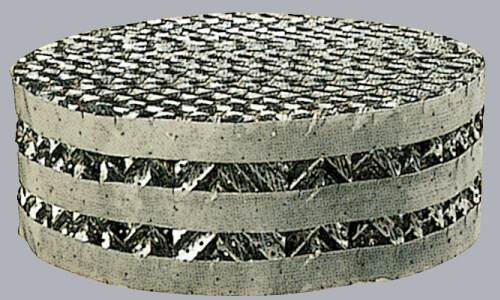

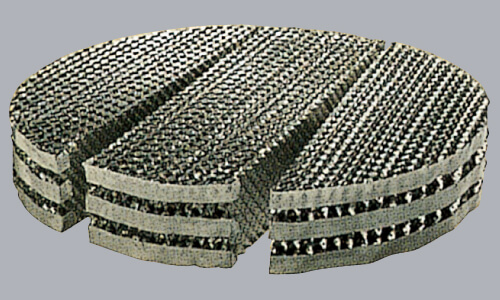

Techno pack’s internal structure of the filling tower

Regularly fillings

TECHNO PACK CERAMIC SADDLE

Metal

Sell, technological development, design and making exploitational by Mitsui & Co., Ltd.

Charater of techno pack

- Small HETP

- Pressure loss is a little

- Easy to scale up

- Large amount of through put

- Having large amount of F factor

- Holding up is a little

Kinds of techno pack and physical characteristic

| type | specific surface area (㎡/㎥) |

void (%) |

gravity (kg/㎥) |

Hight per element(mm) | usage | Tower diameter (mm) |

|

|---|---|---|---|---|---|---|---|

| G500B | Mesh type | 500 | 97.0 | about 185 | about 190 | Cost | 100 above |

| G750A | 750 | 96.5 | about 277 | about 180 | |||

| S250A | Sheet type | 250 | 98.5 | about 88 | about 180 | ||

| S350A | 350 | 98.0 | about 123 | about 180 | |||

| S500A | 500 | 97.5 | about 176 | about 180 | |||

| L900B | Mesh type | 900 | 95.0 | about 378 | about 55 | For examination | 20〜80 |

Techno pack material

| 1.Stainless (standard type) |

|

|---|---|

| 2.Special metal (custom made) |

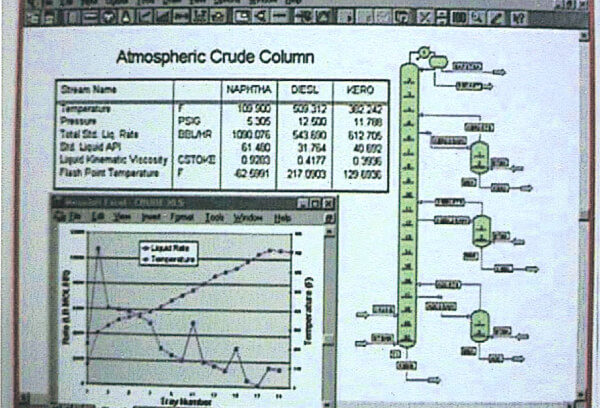

Chemical engineering calculationPROCESS DESIGN

We provide indubitable techniques and products with performance, experience and saving know-how.

Chemical engineering calculation

Simulation: technical investigation by using PRO/II.

Regular fillings (techno pack) and irregular fillings (mini ring and original ring) calculation (Program manufactured by ourself).

◎Drawing new tower

◎Remodeling already settled tower

- ・filling towered tray

- ・changing filling tower

- ・increasing amount of processing

- ・countermeasure energy conservation

- ・decreasing pressure lost △P

- ・capability increase

- etc

- ★Distillation (continuous, batch)

- ★absorption, renewal

- ★extract liquid

- ★stripping

- ★scrubbing, deodorization

- ★rinsing, cooling, drying

Data of process simulation

Requesting Process simulation of a necessity of theoretical plate number and inside tower load from our company, please refer date below.

- Material Balance around the tower (folinate volume, composition, temperature, pressure each stream in (out) of the tower.)

- Operation pressure, temperature

- Demand (or aim) segregation term (example) distilling liquid density under △△% density under △△ppm etc.

- Other estimation or restriction … in case of the fillings, formation of Internals.

Remodeling already-settled tower

- Present kind of filling, size, Hight of filling and type of Internals

- Position relation above

- Remodeling tray tower, position of tray support

Other

- Incase of conversion of already settled tower or the addition, and the objectives.

(example) increasing disposal capacity, increasing segregation etc. - If you have same kind of already settled tower, if you don’t mind. Its operation datum and problems……Especially we do Process Simulation, we use it for data for checking.

Design of hardware

◆All sort of amount volume drawing

- 1.Specific high-pressure gas equipment

- 2.First pressure vessel

- 3.Second pressure vessel

- 4.Small pressure vessel

- 5.Fire protection law etc.

◆design of inner tower

- Distributer

- Hold down plate

- Packing support

- Field & reflux pipe

- Collector tray

◆Self-made program

- Construction code for pressure vessels(corporation of Japan Boiler Association)

- JIS B 8270 pressure vessels

- JPI-7R-35-96 calucuration of the tower buss which having skirt

- JPI-7R-52-96 strength calculation of lay down vessels saddle

- JPI-7R-35-96 lay down vessels saddle

- JPI-7R-71-96 vertical vessel leg

◆Design of parts in the tower

- Distributor

- Hold down plate

- Packing support

- Field&Reflux pipe

- Collector tray

◆Drawing(CAD)

CADSUPER FX for windows Ver7.0

◆3D

Solid Builder Ver2.0